9004-64-2

- Product Name:Hydroxypropyl cellulose

- Molecular Formula:C36H70O19

- Purity:99%

- Molecular Weight:59.08708

Product Details;

CasNo: 9004-64-2

Molecular Formula: C36H70O19

Appearance: white powder

Factory Sells Factory Supply High Purity Hydroxypropyl cellulose 9004-64-2 In Stock

- Molecular Formula:C36H70O19

- Molecular Weight:59.08708

- Appearance/Colour:white powder

- Vapor Pressure:0mmHg at 25°C

- Melting Point:371.06 °C

- Refractive Index:1.531

- Boiling Point:891.2 ºC at 760 mmHg

- Flash Point:492.8 ºC

- PSA:0.00000

- Density:1.27 g/cm3

- LogP:0.00000

Hydroxypropyl cellulose(Cas 9004-64-2) Usage

|

Description |

Hydroxypropyl cellulose (HPC) is a derivative of cellulose being soluble in both water and organic acid. It is excellent in trapping water and preventing water loss. It can be used to treat diseases associated with insufficient tear production such as keratoconjunctivitis sicca, recurrent corneal erosions, decreased corneal sensitivity, and exposure and neuroparalytic keratitis. It is also used as a lubricant of artificial eyes. It can also be used as a thickener, an emulsion stabilizer and binder. Moreover, it can be used as a sieving matrix for DNA separation through capillary and microchip electrophoresis. It is also the major ingredient of Cellugel, which is used in book conservation. |

|

Chemical Properties |

White or yellowish-white powder or granules, hygroscopic after drying |

|

Originator |

Lacrisert,MSD,US,1981 |

|

Uses |

Hydroxypropyl Cellulose is a gum that is nonionic water-soluble cellulose, obtained from the reaction of alkali cellulose with propyl- ene oxide at high temperatures and pressures. it is soluble in water below 40°c, is precipitated as a floc between 40°c and 45°c, and is insoluble above 45°c. the precipitation is reversible with the origi- nal viscosity being restored upon cooling below 40°c and stirring. it is used in whipped toppings as a stabilizing and foaming aid; in edible food coatings as a glaze and oil/oxygen barrier; and in fabri- cated foods as a binder. typical usage level is 0.05–1.0%. |

|

Definition |

A cellulose ether with hydroxypropyl substitution. |

|

Production Methods |

A purified form of cellulose is reacted with sodium hydroxide to produce a swollen alkali cellulose that is chemically more reactive than untreated cellulose. The alkali cellulose is then reacted with propylene oxide at elevated temperature and pressure. The propylene oxide can be substituted on the cellulose through an ether linkage at the three reactive hydroxyls present on each anhydroglucose monomer unit of the cellulose chain. Etherification takes place in such a way that hydroxypropyl substituent groups contain almost entirely secondary hydroxyls. The secondary hydroxyl present in the side chain is available for further reaction with the propylene oxide, and ‘chaining-out’ may take place. Thisresults in the formation of side chains containing more than 1 mole of combined propylene oxide. |

|

Manufacturing Process |

Charge:Procedure: The tertiary butanol, water and sodium hydroxide were mixed and the mixture cooled to 20°C. The purified cotton linters were added to the mixture and aged at 20°C for one hour while stirring. Excess liquid was filtered off the resulting alkali cellulose so that the resulting alkali cellulose filter cake weighed 3.08 parts. This filter cake was broken up and slurried in the hexane, placed in a pressure vessel the pressure of which was increased to 100 psig with nitrogen, and then the pressure was vented to 5 psig. The propylene oxide was added to the pressure vessel and then the pressure was increased to 25 psig with nitrogen. The resulting charge was heated to 85°C in 30 minutes and then reacted at this temperature and 25 psig pressure for six hours. The charge was cooled to 30°C. the pressure vessel vented and 0.14 part of glacial acetic acid added. The excess hexane was filtered off from the resulting hydroxypropyl cellulose product, the product was purified by washing with hot water (85°C to 95°C) and then dried at 130°C using a two-roll drum drier. |

|

Therapeutic Function |

Topical protectant, Ophthalmic vehicle |

|

General Description |

Hydroxypropyl cellulose (HPC) is biocompatible in nature and exhibits low critical solution temperature (LCST). It has been reported to be prepared by reacting cellulose with alkali, producing alkali cellulose which is consecutively reacted with propylene oxide. HPC is soluble in water at lower than RT. Viscosity behaves inversely to rise in temperature. |

|

Pharmaceutical Applications |

Hydroxypropyl cellulose is widely used in oral and topical pharmaceutical formulations. In oral products, hydroxypropyl cellulose is primarily used in tableting as a binder,film-coating,and extended-release-matrix former. Concentrations of hydroxypropyl cellulose of 2–6% w/w may be used as a binder in either wet-granulation or dry, direct compression tableting processes. Concentrations of 15–35% w/w of hydroxypropyl cellulose may be used to produce tablets with an extended drug release. The release rate of a drug increases with decreasing viscosity of hydroxypropyl cellulose. The addition of an anionic surfactant similarly increases the viscosity of hydroxypropyl cellulose and hence decreases the release rate of a drug. Blends of hydroxypropyl cellulose and other cellulosic polymers have been used to improve wet granulation characteristics and tableting characteristics, as well as to achieve better control and manipulation of the rate of drug release. As an alternative technology to wet granulation, dry granulation and direct compression of hydroxypropyl cellulose formulations have been reported to exhibit acceptable tableting and flow characteristics for application in extended-release matrix tablets. Typically, a 5% w/w solution of hydroxypropyl cellulose may be used to film-coat tablets. Aqueous solutions containing hydroxypropyl cellulose together with an amount of methyl cellulose or ethanolic solutions have been used. Stearic acid or palmitic acid may be added to ethanolic hydroxypropyl cellulose solutions as plasticizers. Environmental concerns have limited the use of ethanol in film coating solutions. A low-substituted hydroxypropyl cellulose is used as a tablet disintegrant; see Hydroxypropyl Cellulose, Low-substituted. Hydroxypropyl cellulose is also used in microencapsulation processes and as a thickening agent. In topical formulations, hydroxypropyl cellulose is used in transdermal patches and ophthalmic preparations. Hydroxypropyl cellulose is also used in cosmetics and in food products as an emulsifier and stabilizer. |

|

Safety |

Hydroxypropyl cellulose is widely used as an excipient in oral and topical pharmaceutical formulations. It is also used extensively in cosmetics and food products. Hydroxypropyl cellulose is generally regarded as an essentially nontoxic and nonirritant material. It is not absorbed from the gastrointestinal tract and is fully recovered in feces after oral administration in rats. It does not exhibit skin irritation or skin sensitization. However, the use of hydroxypropyl cellulose as a solid ocular insert has been associated with rare reports of discomfort or irritation, including hypersensitivity and edema of the eyelids. Adverse reactions to hydroxypropyl cellulose are rare. However, it has been reported that a single patient developed contact dermatitis due to hydroxypropyl cellulose in a transdermal estradiol patch. The WHO has specified an acceptable daily intake for hydroxypropyl cellulose of up to 1500 mg/kg body-weight. Excessive consumption of hydroxypropyl cellulose may have a laxative effect. LD50 (rat, IV): 0.25 g/kg LD50 (rat, oral): 10.2 g/kg |

|

storage |

Hydroxypropyl cellulose powder is a stable material, although it is hygroscopic after drying. Aqueous solutions of hydroxypropyl cellulose are stable at pH 6.0–8.0, with the viscosity of solutions being relatively unaffected. However, at low pH aqueous solutions may undergo acid hydrolysis, resulting in chain scission and hence a decrease in solution viscosity. The rate of hydrolysis increases with increasing temperature and hydrogen ion concentration. At high pH, alkalicatalyzed oxidation may degrade the polymer and result in a decrease in viscosity of solutions. This degradation can occur owing to the presence of dissolved oxygen or oxidizing agents in a solution. Increasing temperature causes the viscosity of aqueous solutions to decrease gradually until the viscosity drops suddenly at about 45°C owing to the limited solubility of hydroxypropyl cellulose. However, this process is reversible and on cooling the original viscosity is restored. The high level of substitution of hydroxypropyl cellulose improves the resistance of the polymer to degradation by molds and bacteria. However, aqueous solutions are susceptible to degradation under severe conditions and a viscosity decrease may occur. Certain enzymes produced by microbial action will degrade hydroxypropyl cellulose in solution. Therefore, for prolonged storage, an antimicrobial preservative should be added to aqueous solutions. Solutions of hydroxypropyl cellulose in organic solvents do not generally require preservatives. Ultraviolet light will also degrade hydroxypropyl cellulose and aqueous solutions may therefore decrease slightly in viscosity if exposed to light for several months. Aqueous hydroxypropyl cellulose solutions have optimum stability when the pH is maintained at 6.0–8.0, and also when the solution is protected from light, heat, and the action of microorganisms. Hydroxypropyl cellulose powder should be stored in a wellclosed container in a cool, dry place. |

|

Incompatibilities |

Hydroxypropyl cellulose in solution demonstrates some incompatibility with substituted phenol derivatives, such as methylparaben and propylparaben. The presence of anionic polymers may increase the viscosity of hydroxypropyl cellulose solutions. The compatibility of hydroxypropyl cellulose with inorganic salts varies depending upon the salt and its concentration. Hydroxypropyl cellulose may not tolerate high concentrations of other dissolved materials. The balance of the hydrophilic–lipophilic properties of the polymer, which are required for dual solubility, reduces its ability to hydrate with water and it therefore tends to be salted out in the presence of high concentrations of other dissolved materials. The precipitation temperature of hydroxypropyl cellulose is lower in the presence of relatively high concentrations of other dissolved materials that compete for the water in the system; |

|

Regulatory Status |

GRAS listed. Accepted for use as a food additive in Europe. Included in the FDA Inactive Ingredients Database (oral capsules and tablets; topical and transdermal preparations). Included in nonparenteral medicines licensed in the UK. Included in the Canadian List of Acceptable Non-medicinal Ingredients. |

|

Who Evaluation |

Evaluation year: 1989 |

InChI:InChI=1/C36H70O19/c1-19(37)9-45-17-27-29(47-11-21(3)39)31(48-12-22(4)40)34(51-15-25(7)43)36(54-27)55-30-28(18-46-10-20(2)38)53-35(52-16-26(8)44)33(50-14-24(6)42)32(30)49-13-23(5)41/h19-44H,9-18H2,1-8H3/t19?,20?,21?,22?,23?,24?,25?,26?,27?,28?,29?,30-,31?,32?,33?,34?,35?,36+/m1/s1

9004-64-2 Relevant articles

Solid dosage form comprising solid dispersion and method for producing the same

-

Page/Page column 9, (2008/06/13)

Provided are a solid dosage form compris...

Use of sustained release antibiotic compositions in ophthalmic surgical procedures

-

, (2008/06/13)

An improved method of sterilizing the fi...

9004-64-2 Process route

-

-

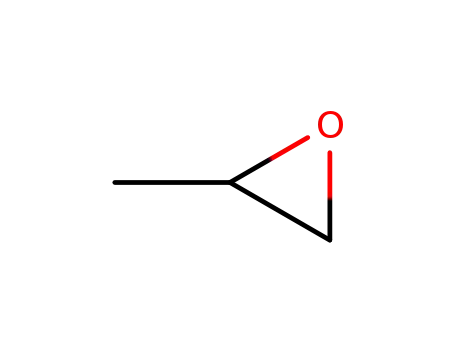

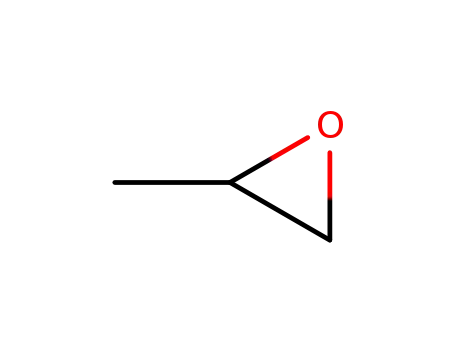

75-56-9,16033-71-9

methyloxirane

-

hydroxypropylcellulose

-

9004-64-2

hydroxypropylcellulose

| Conditions | Yield |

|---|---|

|

at 60 ℃;

for 1.5h;

|

-

hydroxypropylcellulose

-

9004-64-2

hydroxypropylcellulose

| Conditions | Yield |

|---|---|

|

|

9004-64-2 Upstream products

-

75-56-9

methyloxirane

9004-64-2 Downstream products

-

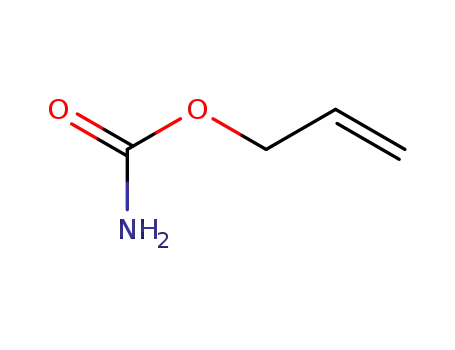

2114-11-6

allyl carbamate

Relevant Products

-

Corticotropin

CAS:9002-60-2

-

ACRYLONITRILE/BUTADIENE COPOLYMER

CAS:68891-50-9

-

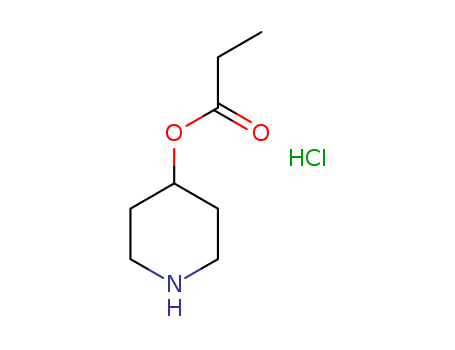

4-PIPERIDINOL, PROPIONATE, HYDROCHLORIDE

CAS:219859-83-3